What is Dye-Sub Fabric?

It’s a product that’s produced through dye sublimation which is the process of heating up transfer dyes onto another material. When the dyes are heated up, they bond with the material and produce an incredibly vivid image that cannot wash off. At SpeedPro Orlando, we print your design to transfer paper first and then transfer the design over to fabric using a heat press. The resulting material is dye-sub fabric and can be used for a variety of products.

Our Process For Dye Sublimated Fabric

Dye sublimated fabric is a very unique product and is on the rise in the market. To help answer any questions about the process for having custom fabric produced, we’ve split the process into several steps below. While these steps may change slightly from project to project, the overall process remains the same.

1. Intended Use & Measurements

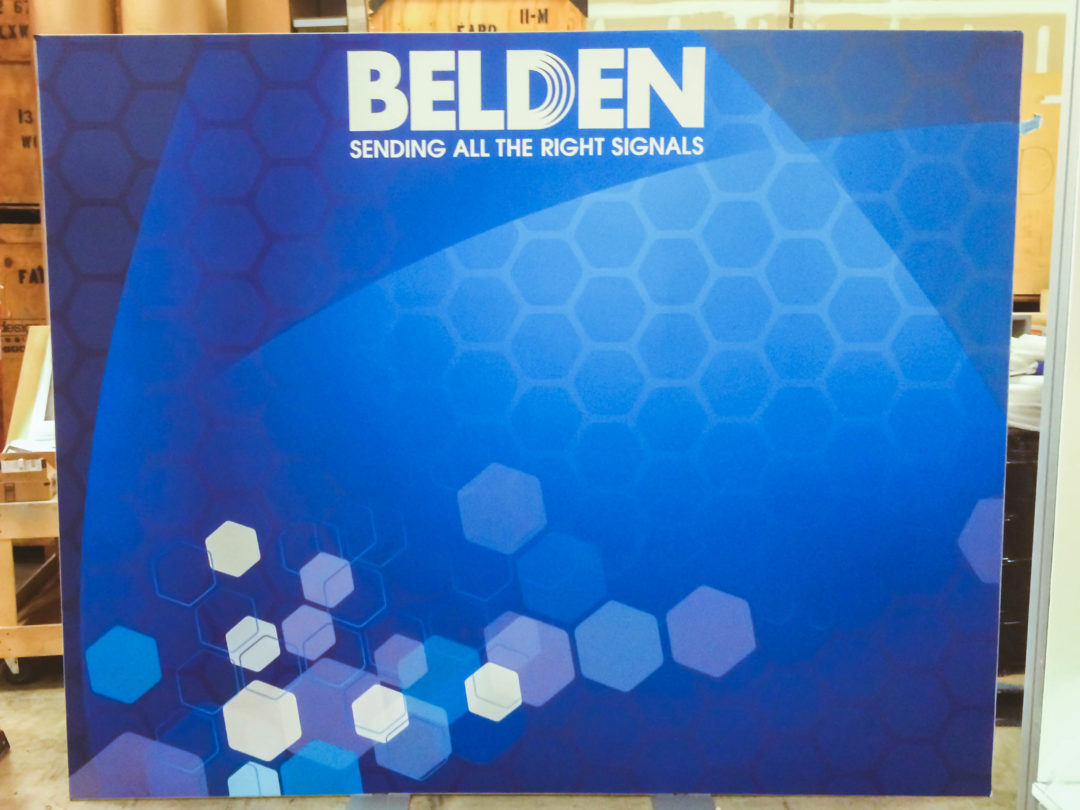

When using fabric, it’s important to know what exactly you’ll be using it for. If you’re unsure what you need, our account managers can walk you through several options to help narrow things down. The reason we need to know which product you’re intending to use it for is that it’ll affect how we produce it and finish it. If it’ll be used for a step-and-repeat banner, we’ll make sure to add pole pockets to it where as with a trade show display, we would likely add a silicone gasket to the edge. Along with that information, we’ll also need the measurements to provide a quote and to produce it.

2. Artwork Files & Proof Approval

To be able to produce the graphics, we’ll need the artwork that’ll be printed on it. Our clients will often have their artwork ready to go and send it through email or through our file uploader on our website. If you don’t have artwork ready to go, just let our account managers know and they can have our design team work with you to create exactly what you’re needing. We’ll also send you a proof with the artwork, measurements, and type of fabric that will be printed. Once you approve it, we’ll send over the files to our production team.

3. Printing & Finishing

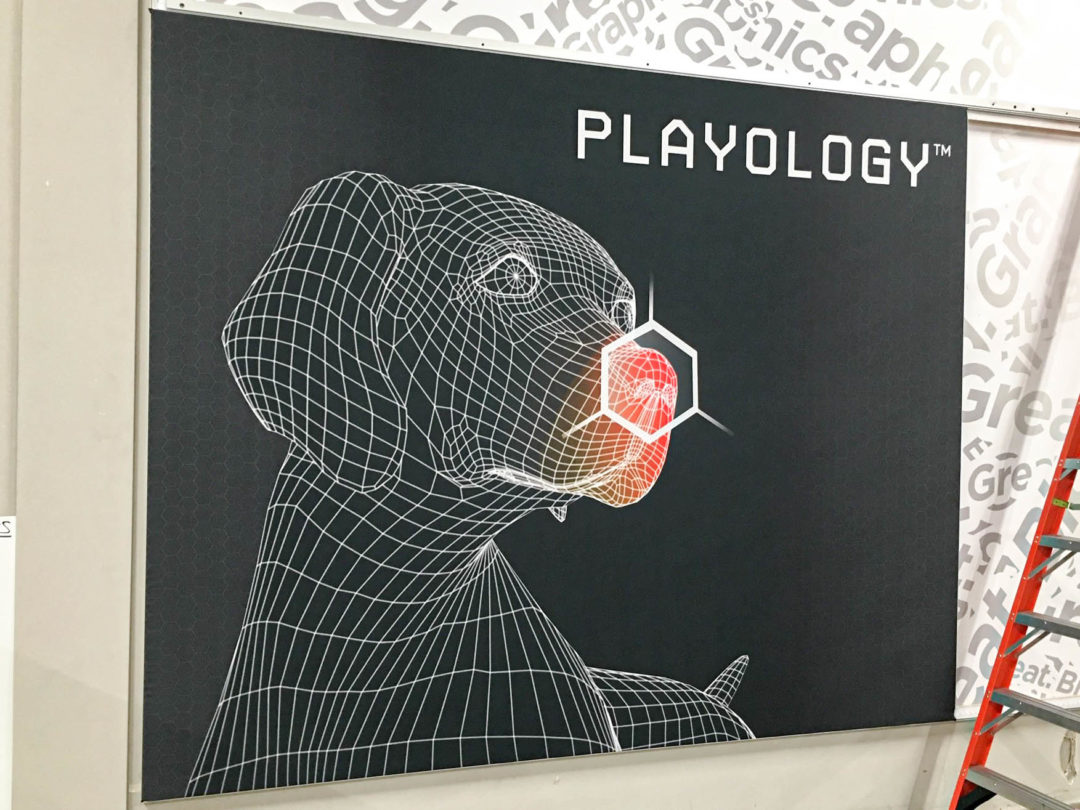

Fabric graphics are produced in a very unique way when compared to the other graphics that we print. We first reverse print your design to transfer paper and then run the transfer paper along with the fabric through our heat press. When it goes through the heat press, the sublimation process happens. After the design has been transferred, we hand over the graphics to our sewing team and they complete the finishing that may need to be done.

4. Installation & Shipping

The last step of our process is the installation or shipping of your products. If you’re needing graphics installed, our account managers will find a time within your schedule to have our in-house installation team accurately and precisely install the fabric graphics. Our installation team is extremely professional and always focuses on the task at hand to allow for minimal disruption to you and(or) your team. If you’re outside of Florida, we can ship your graphics directly to your facility, trade show, event, etc.

Dye sub fabrics are the future of signage. The vibrant colors and versatility will not only impress you, but all of your customers as well.

Benefits of Using Dye Sublimated Fabric

- Durable: The design that was transferred to the fabric won’t fade or crack. The inks are bonded with the fabric and not sitting on the surface as they are with rigid substrates. You’ll even be able to wash the fabric while retaining the design on it.

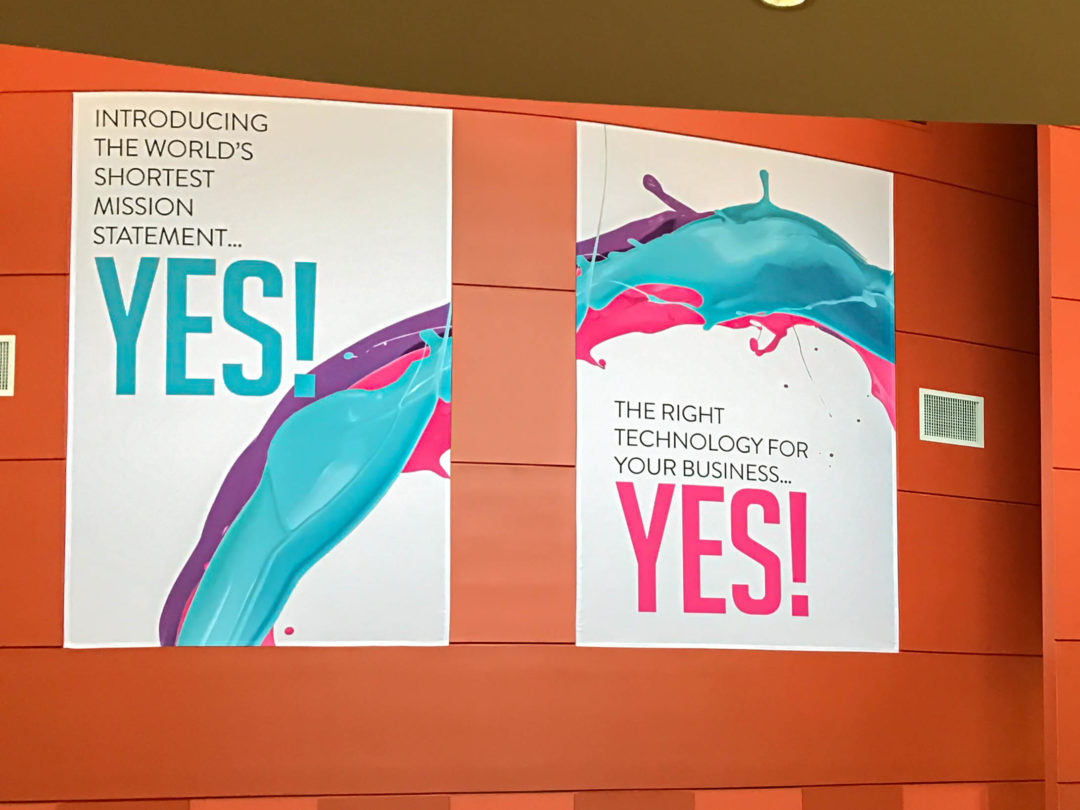

- Vibrant: It’s possible to achieve a wide range of vibrant colors throughout your graphic as the fabric will show the variations very well. When it’s all said and done, the graphic tends to be more on the saturated side. Use the saturation to your advantage by showcasing the fabric in a well lit area or by mounting the fabric to a lightbox. The resulting image will be jaw dropping.

- Compact: Dye sub fabrics are much easier to ship than typical large format graphics. With fabric, you’re able to fold it up without having to worry about damaging the product. That also means that they’re much easier to store as well. Storing fabric is perfect when you have seasonal graphics or when you change out the design often.

- Glare Free: Unlike wall coverings and wall vinyls, fabric graphics are completely glare free. They’ll be easy to see and you won’t have a distracting glare.

Dye Sublimated Graphics in Central Florida

We’ve worked hand-in-hand with our community to generate remarkable results and create state-of-the-art graphics. From vehicle wraps to trade show displays, we know how to enhance your image and make you stand out. Servicing Orlando, Kissimmee, Lake Buena Vista, Sanford, Apopka, Winter Park Altamonte Springs and many other areas, SpeedPro Orlando acts as a trusted partner to Central Florida.

Types of Dye Sublimated Fabric

We dye sublimate quite a few products. If you’re looking for a specific product, check out our links below. You can also request a consultation and we’ll walk you through our full range of products and services.